ASM IC packaging equipment ASM Pacific won the MINI/MICRO LED expert Aurora Award for the second year in a row! What are the VORTEX’s reasons for winning?

EXPERTS SAY DISPLAY GUIDE:

The two-day conference was held in Shenzhen on December 1-2, with several awards being announced. Asm Pacific’s Mini LED VORTEX, a new crystal-fixing machine, won the “Mini & amp; Micro LED device product of the year Gold Award.”. Chan chi-yung, senior sales director of Asm Pacific, said that it is a special honor for Asm Pacific to win the Gold Award for equipment of the year for two consecutive years, and thanked customers for their support and recognition. He believes that the average customer has realized that traditional technologies can no longer be applied to Mini/Micro leds, and that in this age of automation, intelligent production and intelligent plant configuration have slowly become the basic requirements of the device, aSM Pacific will continue to help customers automate and mass produce Mini/Micro leds.

Adepts Aurora Awards Gold Award Presentation Ceremony

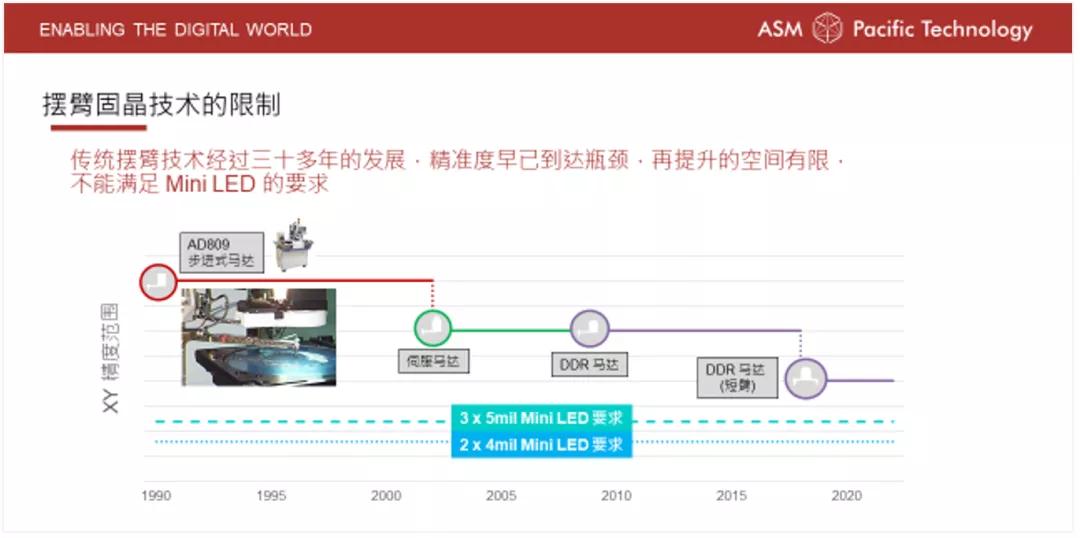

ASM Pacific has been standing in the field of LED solid crystal for more than 30 years, has been in the forefront of industrial development. 1990s’s first generation LED crystallizer has followed the traditional swing arm welding head, after decades of development and optimization, its accuracy has already reached the bottleneck, can improve the space is limited, can not meet the requirements of the Mini LED.

Limitation of arm hardening

In view of this, ASM Pacific independently developed a new welding head technology, VORTEX for the need to place small size LED chips large LED display to provide high-speed, high-precision Mini LED solutions. The key functions and parameters of the VORTEX are as follows:

1. Mini LED processing power: LED chip size 3x5mil ~ 5x9mil

2. XY calibration capability to achieve high accuracy: XY ± 15um@3σ * ; θ ± 1 °@3σ *

3. Ultra-micro spacing processing, the smallest P0.4 LED display solid crystal

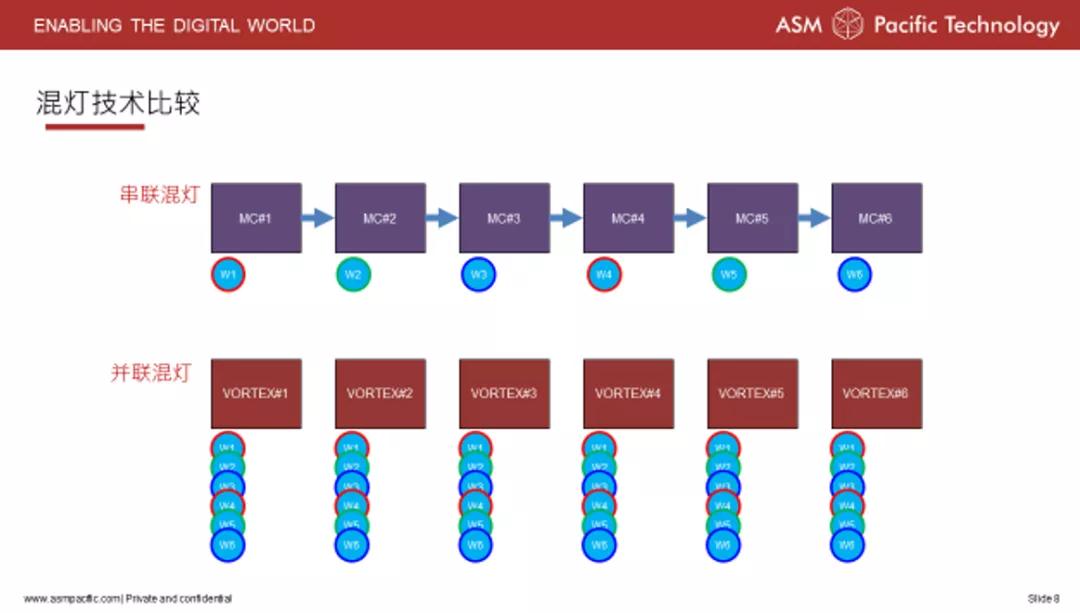

4. Color mixing technology, parallel mode of the Hybrid Bin Technology

ASM Pacific Mini LED new solid crystal machine VORTEX

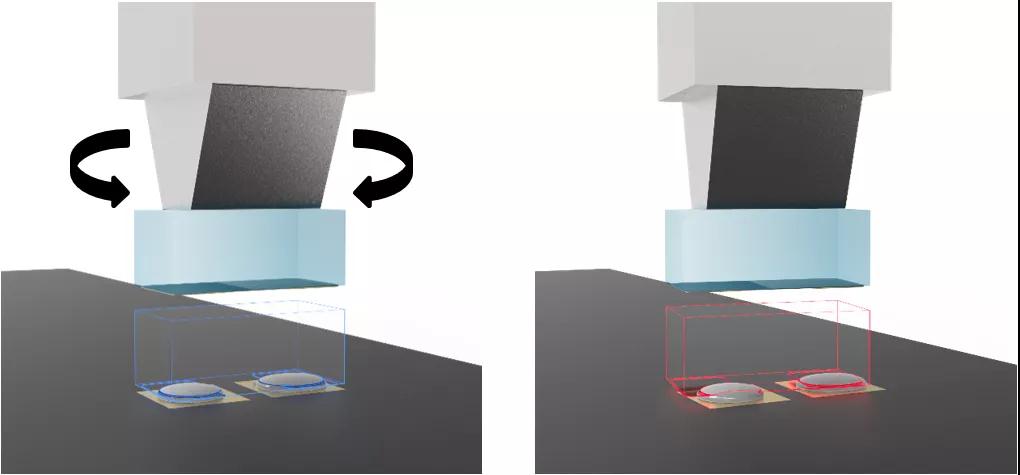

Vortex can process Mini leds and is equipped with a self-correcting solder joint technology with calibration capabilities. This is because: compared with the traditional LED chip, the size of the traditional solid-crystal machine ± 25um has an order of magnitude difference, so the effect of the solid-crystal error is not significant. But in the Mini LED stage, the chip size is below 200um, the distance between the chip electrodes is below 100um, the error caused by the solid crystal precision of ± 25um and the angle precision of ± N + 2 ° will be amplified. That is, the smaller the LED chip size, the higher the solid-crystal precision requirements.

Left: Auto correct feature exclusive to Vortex, ensures Mini LED accuracy | right: no auto correct feature, precision is difficult to control

There are two main reasons for the deviation of the Mini LED chip, one is that the chip is separated from the wafer and has already been deflected on the chip, and the other is that during the process of grabbing the chip, the ejector pin pulling the blue film aggravates the chip deviation. Vortex’s stand alone correction solder head is specially designed for the Mini LED flip chip. After grabbing the chip and fixing the chip, the bottom of the chip is checked and the position and angle are corrected in real time to ensure the precision of the solid crystal and the correct position of the PN. In addition to high yield, more to ensure high brightness rate, and the correction process is not to damage production capacity, to high-speed, high-quality effect.

Intermission: join the Mini LED industry community, please add VX: hangjia188

In addition, Vortex has added another feature to the Mini LED’s technological features: Because the Mini LED is packaged in an integrated way, it can not be mixed in the Bin process after solidification, so VORTEX uses the mixed Bin technology, beating mode, to achieve the edge of mixing Bin Solid Crystal.

ASM太平洋VORTEX采用并联混灯技术

VORTEX'S HYBRID BIN technology works in parallel. Based on the mature mixed-Bin technology, combined with exquisite design, a single machine can handle RGB color mixing, can realize independent production, the conversion time required for production is shorter, the production process is simplified, the life of solder paste is easy to monitor, and other advantages are convenient for production management, more suitable for mass production.

The VORTEX with the new type welding head has the Mini LED processing ability, the XY θ correction function, the color mixing technology, the ultra micro spacing processing function, may carry on the solidification to the P0.4 ultra micro spacing LED display screen, high productivity can be maintained while ensuring that the VORTEX can achieve true high-precision solidification.

Vortex can cooperate with automated production link In-Line Linker or SIS-OPTO, enhance the level of automation, so that the equipment can operate intelligently, 24-hour uninterrupted production, in order to save labor costs, area while lifting equipment output.

ASM Pacific In-Line Linker automatic production line

ASM Pacific SIS-OPTO intelligent production workshop

Experts say Research believes the market for Mini leds is growing fast and industry-related manufacturers are putting them into production. Solid Crystal Machine is one of the most important equipment in the production line, manufacturers need to be careful when purchasing equipment, because to a large extent determines the process of mass production. While the cost of the initial investment should be considered, the sunk cost should also be considered. The new Mini LED crystallizer has a large investment in the early stage, but it will bring more reliable yield, efficiency improvement, and then bring about the improvement of production efficiency.