Times have changed? Why did the old crystal fixer have trouble with the Mini LED?

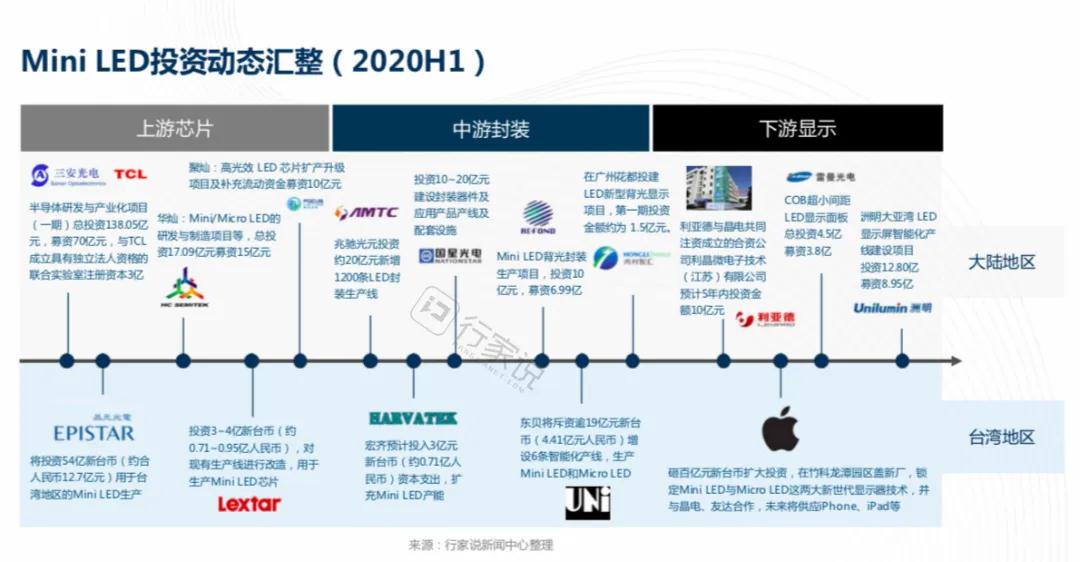

Traditional LED display market is a Red Sea, but with the increasing demand for visual experience, technology constantly updated, Mini LED came into being, LED leaders have stepped out of the original business areas, the industry chain upstream and downstream have bet. Apple is expected to launch a Mini LED tablet and laptop by 2021; Samsung will launch a Micro LED (Mini LED) The Wall series; and crystal and Liad Will Invest Heavily in research, development and production of Mini leds in alliance with Prayer flag. Not only that, but in the first half of 2020, manufacturers in the upper, middle and lower reaches of the industrial chain across the Taiwan Strait invested in Mini leds, according to experts at the News Center.

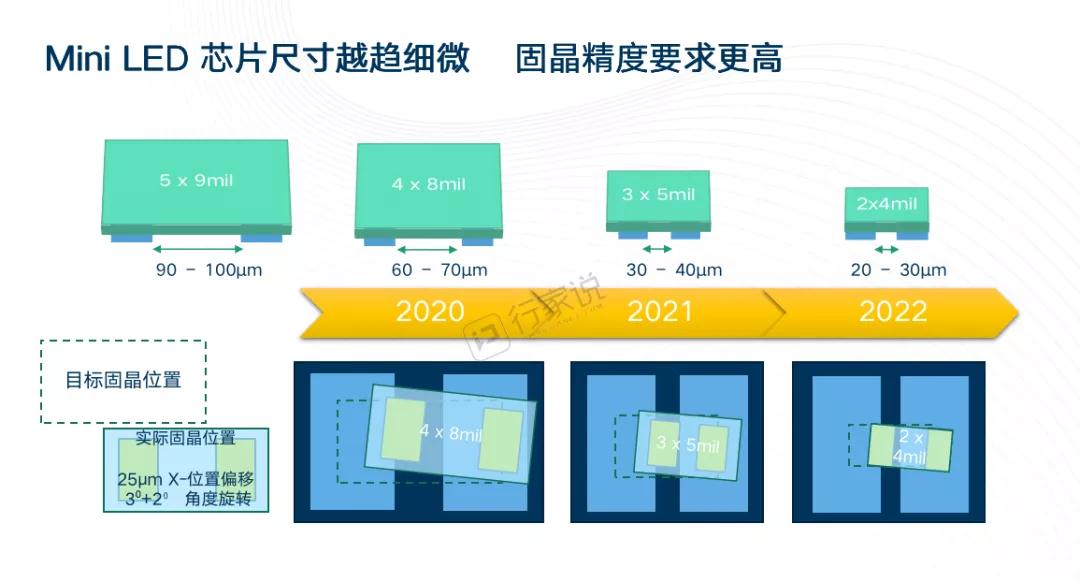

As a new generation of display technology, the Mini LED has become increasingly popular. But as chip sizes get smaller and smaller, the very important transfer and solidification links, traditional equipment has encountered bottlenecks. Recently, it was announced that the company is purchasing a large number of high-speed transfer and solidification equipment for Mini leds. Samsung is also looking for new solidification equipment for Mini leds. The traditional double-arm design has been excluded due to some defects. So, what’s wrong with the old-fashioned dual-arm swing that’s no longer considered by manufacturers to be a Mini-LED solid crystal? According to experts, data from the Industrial Research Center shows that the traditional solidification equipment uses double-arm swing welding head, the biggest disadvantage is that the welding head has no correction function, precision is difficult to guarantee. In short, in the process of transfer and consolidation, to ensure two precision: solid precision and angular precision. Solid-crystal precision XY refers to the precision matching degree between chip drop point and target solid-crystal position XY coordinate. Angle accuracy θ refers to the precise matching degree between the electrode of flip chip and the contact surface of the solder joint. In addition, the chip from the epitaxial cut down to transfer to the Blue Film will occur angle deflection, and solid-crystal capture chip process of pulling the blue film, may also make angle deflection more serious, these will further affect the precision of solid-crystal. These problems can be ignored in the traditional LED package, because the traditional LED chip size is large enough compared to the Mini LED, ± 25? Compared with the traditional LED chip, the size of m solid-crystal precision XY has an order of magnitude difference, so the effect of solid-crystal error is little.

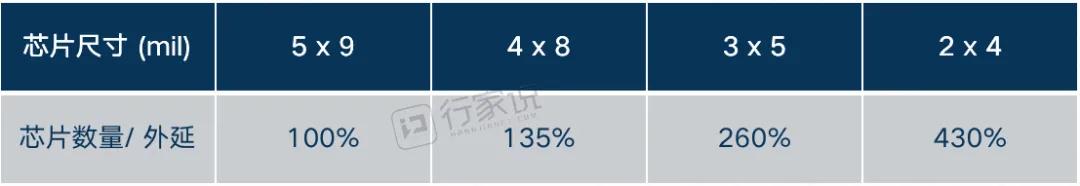

But in the Mini LED phase, the chip size is about 200? Below M, the distance between the chip electrodes is 100? Below M, ± 25? The solidification precision of M is XY and ± N + 2? The angular accuracy of Theta will be significantly magnified. It can be said that the smaller the size of the Mini LED chip, the higher the solid-crystal precision requirement. The smaller the chip size, the smaller the screen can achieve a smaller point spacing or a smaller percentage of the area of the light source, thereby improving the display. In addition, the price of the Mini LED chip is positively correlated with the chip area. The smaller the chip area, the more chips can be cut out per epitaxial chip, and the lower the price of a single chip.

In order to pursue better display effect and lower cost, the trend of Mini LED display in the future is developing in the direction of chip size miniaturization. Therefore, instead of investing in seemingly cost-effective devices that will be phased out by the industry in the next few years, it is better to follow the rules and invest in a new high-precision crystal-setting machine for Mini leds in advance to firmly grasp the first-mover advantage. So, is there currently a device manufacturer that can provide high-precision Mini LED solid-crystal devices to address these pain points? According to the Industry Research Center, the major devices on the market that can offer new solid-crystal technology for Mini leds are Asm Ad420, k & AMP; s and Rohinni’s Pixelux, each of these vendors has its own Mini LED crystal fixation technology. According to the Mini LED applications are mainly divided into backlight and self-luminous display, K & AMP; s and Rohinni devices are mainly for backlight applications, Asm Pacific is a two-pronged. The ASM Pacific’s AD420 is comparable in accuracy to k & AMP; s and Rohinni’s Pixelux, but k & AMP; s and Rohinni’s Pixelux solid-crystal process has no independent correction function, the error caused by other factors is not easy to control, so it has some instability. Sources close to the Industry Research Center said Asm was used in both the Mini LED backlight and the Mini LED self-illumination. Therefore, Samsung and crystal in the procurement of new Mini LED solid-crystal equipment, it can be based on the actual needs of the assessment of consideration. From the perspective of the layout of the major manufacturers, the future Mini/Micro leds will be a competitive place in the industry. When replacing traditional solid-crystal devices, we must be cautious and prudent as an asset investment, which largely determines the speed of the mass-production process, or even directly determine the success or failure of the product. Purchase new equipment, of course, to consider the cost of the first investment, but also to take into account sunk costs. The new Mini LED crystallizer may have more upfront investment, but it brings more reliable yield and efficiency improvements, which in turn leads to higher production efficiency. It will eventually thin out fixed costs in terms of output, giving the Mini leds a head start on cost advantage, winning the arms race for a new generation of display technology, and speeding up the process of making the human experience better and faster. In, under the background of 5G, under the influence of the new coronavirus epidemic, what are the opportunities and challenges for the LED display industry in the battle with the LCD camp? What new worlds have Mini/MicroLED opened for commercialization? Snow Intelligence, in conjunction with the China and AVC, and experts at the core of the industry chain, as well as participants in the white paper on small spacing LED research, will interact from a technical and application perspective, experts at the symposium said, through the transmission of valuable industrial information, to accelerate the commercialization of cutting-edge technology and industrial integration and upgrading.