How does ASM wire bonder cater to the rapid development of mobile camera?

Since the advent of 5g network, major mobile phone brands have successively launched 5g smart phones. Regardless of the price of mobile phones, consumers' matching requirements and performance of mobile phone cameras have increased. With the progress of science and technology, many people use mobile phones to replace traditional digital cameras to shoot daily life and share with friends. In recent years, the camera development of smart phones has indeed become more and more powerful, with more and more functions and more pieces. From the former shooting capacity of 1.3 million pixels to today's 100 million pixel, high-power optical zoom, wide scene, night mode shooting 3D depth sensing and ultra-thin front camera, etc. From the technical level, this means that the camera components, mirror base and production also need to be changed relatively.

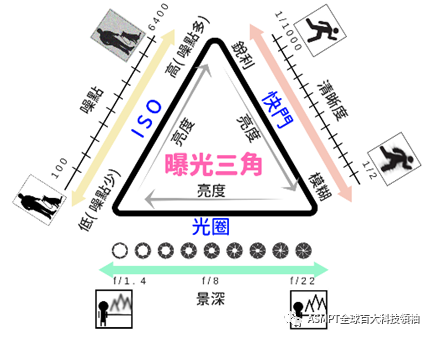

Reviewing the basic concept of shooting images, it is necessary to balance the "exposure triangle" (ISO level, shutter and light storage) in order to achieve high quality. Since the photosensitive element at each point represents the corresponding photo pixel, when the photo pixel is raised, that is, the pixel of the photosensitive element also needs to be denser and smaller at the same time. In this way, the photo will have the problem of insufficient light source (if other configurations remain unchanged), and the "exposure triangle" will be unbalanced and the photo will become darker. The most direct way is to expand the lens diameter so that more light sources can go directly to the photosensitive elements. Although this solves the problem of "exposure triangle", it also leads to problems such as shallow depth of field and difficulties in production.

Therefore, optical designers have designed multi-layer lenses to be stacked into lens seats. The more layers of lenses, the better the imaging quality will generally be. However, the traditional camera assembly technology is aligned and assembled according to the appearance characteristics of the lens and the sensor, but the optical axis has no coaxial relationship with the actual external size. The larger the superposition tolerance of parts, the worse the pixel quality will be. When assembling multi-layer lenses, errors of inclination and eccentricity often occur, and finally the photos will become blurred, the clearest position deviates from the center of the picture, and the definition of the four corners is uneven, which affects the quality of the camera and causes the loss of yield. Therefore, they cooperated with equipment manufacturers to make self-contained mirror base alignment technology.

Although the autonomous mirror base alignment technology has been applied in the market for several years, it still needs continuous development to meet the rapid changes in the mobile camera market. With the increasing number of lens layers, the optical path will become extremely complex, and the requirements for optical axis alignment of lenses will also increase. The previous 6-axis alignment technology can no longer support today's mainstream functions such as ultra-high pixels, extra long focal length, folding and ultra wide-angle cameras. Therefore, camera manufacturers need to cooperate with equipment manufacturers to carry out more accurate alignment through more axes, To enhance the multi-layer lens.

However, few equipment manufacturers can really master the technical know-how and have a full understanding and understanding of optics. They can apply the concept of autonomous mirror base alignment technology incisively and vividly. In addition to mechanical design, they should also cooperate with different processes, optical calculation and process optimization. The most important thing is to adhere to the industry and integrate many years of experience in cooperation with end customers at home and abroad, Can help manufacturers effectively produce valuable products and prepare for higher quality cameras in the future.

The iPhone 12 uses a 7p lens, which has seven layers of lenses. In order to improve the imaging quality, 8p and even 9p high-end cameras are also developing (picture source: online pictures)

ASM Pacific has continued to develop new technologies since it won the Hong Kong Industrial and commercial award and scientific and technological achievement award with is600gs in 2017. At present, ASM Pacific's autonomous mirror base alignment technology has developed to a 12 axis accurate alignment mode. This technology is the world's first and has been applied to the latest Autonomous mirror base alignment system of ASM Pacific, At the same time, ASM Pacific is working hard to develop new technologies to meet the needs of the future market.

ASM Pacific's latest generation of autonomous mirror base alignment system gs-plus can flexibly handle different camera focal segments, folding camera modules, ultra wide angle cameras, ultra-high pixel cameras, etc. The real-time detection system classifies the materials before the alignment of the mirror base, and configures four groups of synchronous alignment design to reduce the cost and greatly increase the output, so that the manufacturer can achieve the best balance between quality and production capacity.

In addition, the CIS equipment of ASM Pacific is equipped with idealine? System, fully automatic production scheme, greatly improve the automatic production of the plant, improve the yield and save manpower. Enable manufacturers to achieve industrial 4.0 and intelligent production. Adhering to today's market advantages, ASM Pacific will continue to drive the technological development of CMOS camera sensor equipment and explore the digital world.